PCB Rework/ Repair Consumables

PCB Rework/ Repair Consumables – In order to do PCB repairing, a number of soldering and repairing consumables are essential.

The truth is that no soldering operation produces perfect assemblies each time. Even the very best nice additives fail from time to time. That’s why information to remodel and restore techniques and substances is so essential to maintain, or restore Printed Circuit Boards (PCBs).

How lesser thermal pressure on additives may be decreased even as repairing/ transforming on a PCB?

While operating on repairing a PCB the principal goal is to warm and eliminates the solder joint. But the factor as quickly as viable to keep away from heating surrounding regions as lot as viable.

Heating the solder joints is required to be simpler for removing the faulty additives. Also, the appearance of the assignment quickly with one try reduces thermal stress on different regions. Solder wick or desoldering stations are proper rework consumables to eliminate solder from remote regions.

Soldering is a reasonably easy idea of mixing steel surfaces with the use of warm soldering iron, flux, and solder. But removing the equal solder if something isn’t always proper is extra difficult. Bad additives may also want to be eliminated and replaced, or immoderate solder may also want to be eliminated, like bridging among contacts.

Need for different PCB Repair Consumables

What is a Solder Wick?

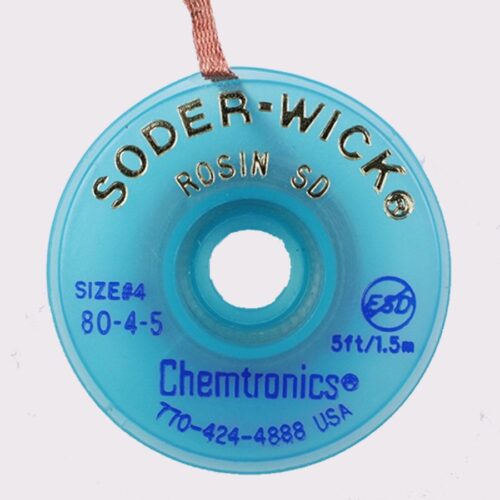

Solder wick, Desoldering braid, or just wick are all names for a copper braid this is used to take in solder. The wick is covered with flux, so while heating, the melting solder is drawn out and retains the use of a mixture of wetting and capillary action. Solder wick lets you eliminate solder in remoted regions without thermally stressing the general board or close-by additives.

It can simply eliminate uncover solder, so additives protecting regions, like ball grid arrays (BGAs), ought to be eliminated earlier than the residual solder. Solder wick is available in extensive sort of widths to efficiently eliminate solder from extraordinary sorts of touch regions.

It can be easily fit for the unique soldering process: rosin, no-smooth, to feature your very own flux as you operate it.

Flux Pens are used for The Soldering Process

- Conductive Pen: The microtip conductive pen creates great conductive traces on epoxy, glass, plastic, and steel surfaces. This is one of the PCB Repair Consumables, which gives smooth functioning.It is widely utilized in repairing PCB tracks, linking PCB additives, and making smooth jumpers. It includes advanced nice silver which offers excessive conductivity and corrosion resistance properties.

- No-Clean Flux Pens: This no-smooth flux is put together to carry out at the right temperatures of lead-free soldering. However, it is likewise powerful for tin-lead soldering as well.It’s designed with low floor anxiety to save you bridging. But Post-soldering cleansing is elective due to the fact the light residue left after soldering is slightly substantive, non-corrosive, and halide free. This is a great preference for tin-lead soldering wherein cleansing is to be avoided.

- Rosin Flux Pen: This is an excessive solids kind of Rosin flux that offers amazing solderability. It is an extensive sort of application. The residue left at the back is non-corrosive and is halide-free; however, it’s miles great to eliminate the residue after soldering for aesthetics.

- Water Soluble Flux Pen: This is a completely lively pH impartial ORH1 flux. It permits smooth soldering of each lead-free and lead-containing solder. This flux needs to be wiped clean and maybe get rid of without problems with DI water.

Sumitron is the right place for all these PCB repair consumables with good quality products at the best price to meet the customer’s needs.