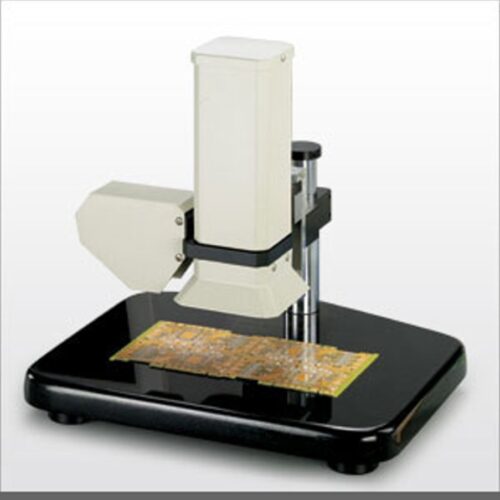

Laser Vision Measurement

Ambitech GAM-70 (Laser Vision Measurement) is used to measure thickness and dimension for other objects. It is utilized in inspecting the quality of Tin solder on PCB (Printed Circuit Board).

It can deal with an increase in the growth of fine pitch and enhance printed technology with high precision. Laser Vision GM-70 prevents various kinds of defects from the printing process like bridging, deviation, location, etc.

GAM-70 can calculate the measure of area, a measure of volume, and cross-sectional area automatically. Also, it can calculate the manufacturing ability degree automatically. All the operations are easy and user-friendly.

You can save all the examine values in a file and get print-out reports instantly. GAM-70 can separate records automatically to different production lines. The focal distance can be adjusted in different thicknesses of the PC Board.

Features of (GAM-70) Laser Vision Measurement

- It is easy to operate, and fast to gather printed data for reference.

- Analyze the thickness of the solder cross-sectional area.

- For real-time data quality control, statistical charts, and process capability index is available.

- It can provide a control diagram, R control diagram, single point list diagram, and thickness list diagram.

- Survey the quality of the solder printing process.

- It can display a full-screen image.

- Display and print all the statistics and distributive thickness charts.

- Analyze the percentage for distributive thickness.

Advantages of Surface Mount Technology

Surface-mount technology was created during the 1960s and was comprehensively utilized during the 1980s. And till the 1990s, they were utilized in most top-of-the-line PCB gatherings.

Traditional electronic segments are upgraded to incorporate metal tabs or end covers that can be joined straightforwardly to the board surface.

This supplanted regular wire drives which expect to go through penetrated openings. SMT prompted a lot more modest parts and empowered segment arrangement on the two sides of the board more much of the time than with through-opening mounting.

Surface mounting empowers a more significant level of mechanization limiting work costs and growing creation rates bringing about cutting-edge PCB plans and improvements.

This innovation is known as Surface Mount Technology( SMT) and SMT parts. Basically, the entirety of the present equipment that is designed financially utilizes surface mount technology.

SMT, on the grounds that it offers critical preferences during PCB fabrication, and considering the size the utilization of SMT parts empowers undeniably more hardware to be pressed into a lot more modest space.

Notwithstanding the size, surface mount technology permits computerized PCB gathering and fastening to be utilized, and this acquires critical enhancements dependability just as huge reserve funds in expense.

Why Choose Sumitron for Laser Vision Measurement?

We at Sumitron.com provide the best solutions for major industry sectors in India and around the world. We are the leading distributors and suppliers of industrial equipment, tools, and materials.

Sumitron has a well-stocked warehouse that includes essential tools, spare parts, etc. for our valued customers. We believe in Quality, Reliability, and Convenience to achieve excellence in service and customer satisfaction.