Selective Soldering

Selective soldering is the process of soldering components to circuit boards (PCB) selectively and molded modules that might be damaged by the overheating wave soldering during a traditional Surface-mount technology (SMT) or Through-hole technology assembly processes. With the growing popularity of SMT technology, through-hole technology is taking over less land on a PCB assembly. But through-hole pins are still a necessity for several boards, and they still got to be soldered.

While this process is often cumbersome, many manufacturers have turned to selective soldering as a particular and cost-effective thanks to solder through-hole technology. Hand soldering is not always accurate, also slow, and costly, but selective soldering allows soldering through-hole pins and works around delicate and sensitive SMT packages on specific areas of the board.

This promotes repeatability – and thus, fewer defects, increased throughput, and overall cost reduction. There are alternative ways to execute selective soldering, but it’s best with a programmable machine. This technology has its own set of challenges like other soldering processes. Because it [Selective Soldering] applies heat to only one place on the board. The flux contained within the solder paste won’t activate properly and can cause flux residue to spread to other parts of the board.

Ionic contaminants contained within the flux residue aren’t easily detectable, and this sort of ionic contamination could eventually cause dendritic growth later within the board’s lifecycle. A method to beat this challenge is to preheat the board before the process so that the flux can better activate. Using this method, you’ll mitigate flux migration.

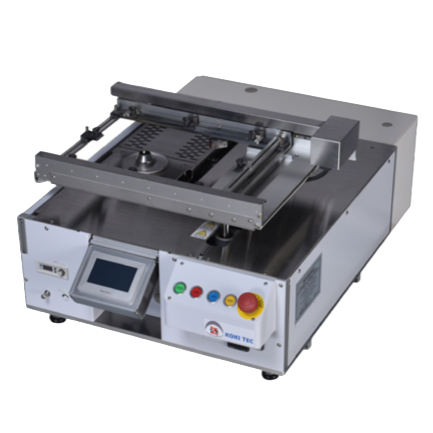

Selective Soldering Machine Prices & Quality

Sumitron provides highly flexible and accurate selective soldering machines at fair prices to our customers. The sales of those machines have tapped out the popularity and consumer base to the subsequent level. If you would like to experience the most superficial quality selective soldering machine with cent percent reliability, then we are those to be considered.

Tsutsumi Mcross TX m444A 4-Axis Soldering Robot

Majorly used for point and slide soldering during a wide selection. The aluminum base present gives it good rigidity. It also helps to achieve accurate repetitions and perform a decent carrying capacity. Adjustment of feeding amount, feed rate, and soldering wire temperature is out there alongside high memory and data storage.

Tsutsumi IMPACIII TS-711

This selective soldering machine features a mind of its own. It allows the registration of up to 31 soldering conditions, which successively can check for hand tool tip temperature, clogging of solder, etc. These machines even have an error-reverting feature alerting problems and data storage capability.

Sumitron stages foreign tools for various industries like Electronics, Pharma, etc. We pledge to deliver the most superficial quality, reliable and user-friendly products. Additionally, our constant customer support grabs us a giant arm of consumers. Our portal may be a hub for Soldering, Inspection devices, Screwing tools, cables, and lots more. If you’re trying to find a highly flexible selective soldering machine, then look no further.

We at Sumitron provide the best solutions for major industry sectors in India and around the world. We are the leading distributors and suppliers of industrial equipment, tools, and materials.