In the world of electronics manufacturing, precision and reliability are paramount. As technology continues to advance, circuit board designs become increasingly complex, with smaller components and tighter spacing. This evolution has given rise to the need for specialized soldering equipment capable of meeting these intricate demands. Enter selective soldering equipment, a game-changer in the electronics manufacturing industry. In this blog post, we’ll explore the best selective soldering equipment, what selective soldering is, its benefits, and how this equipment is transforming the manufacturing process.

What is Selective Soldering?

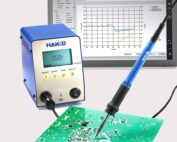

Selective soldering is a soldering technique that allows manufacturers to precisely target and solder specific areas of a printed circuit board (PCB). Unlike traditional wave soldering or reflow soldering methods that cover the entire PCB with solder, selective soldering equipment provides a level of accuracy and control that is essential for modern electronics. It allows manufacturers to solder only the desired components while avoiding adjacent ones.

Benefits of Selective Soldering Equipment

- Improved Precision: The primary advantage of selective soldering equipment is its ability to provide pinpoint accuracy. This precision reduces the risk of solder bridges, cold joints, and other soldering defects that can compromise the functionality of electronic devices. Manufacturers can confidently solder fine-pitch components and connectors with ease.

- Reduced Heat Exposure: A selective soldering system minimizes the exposure of sensitive components to excessive heat. By directing solder only to the intended areas, nearby components are shielded from potential damage caused by prolonged exposure to high temperatures. This is particularly crucial for components like surface-mount devices (SMDs) and delicate connectors.

- Enhanced Cost-Efficiency: While selective soldering equipment represents a significant investment, it pays off in the long run. Manufacturers save on material costs as they use less solder, and they also reduce rework and scrap due to soldering defects. The improved quality and reliability of solder joints lead to fewer warranty claims and returns.

- Process Flexibility: Selective soldering equipment is versatile and can be adapted for various soldering applications. Whether it’s through-hole components, connectors, or complex PCB assemblies, these machines can accommodate different production needs. Changeovers are quick and easy, making it an efficient choice for high-mix, low-volume manufacturing environments.

- Environmental Friendliness: Selective soldering machines generate less waste compared to traditional soldering methods. The controlled solder application reduces excess solder and minimizes the need for cleaning processes. This translates to a more eco-friendly and sustainable manufacturing process.

How Does Selective Soldering Work?

Selective soldering equipment employs a combination of precision nozzles, flux applicators, and programmable robotic arms to control the soldering process.

Here’s a simplified step-by-step overview of how it works:

- Flux Application: A precise amount of flux is applied to the specific areas of the PCB where soldering is required. Flux helps clean the surfaces and ensures proper solder wetting.

- Component Alignment: The robotic arm positions the PCB and components precisely under the soldering nozzle.

- Soldering: A precise amount of solder is dispensed from the nozzle, targeting the solder joints of the components. The solder melts upon contact with the preheated component and PCB pads.

- Cooling and Solidification: After soldering, the assembly moves to a cooling station where the solder solidifies, forming reliable connections.

For more information log in to @sumitron.com

Our Top Products:

- Smoke Absorber

- Soldering Iron

- Automatic Tape Dispenser

- Rework Station

- Automatic Label Dispenser Machines

Related Blogs:

Hello There. I discovered your blog the use of msn. That is an extremely neatly written article.

I will make sure to bookmark it and come back to learn more of your helpful info.

Thank you for the post. I will definitely comeback.