Tsutsumi Mcross TX m444 A4 Axis Soldering Robot

Tsutsumi Mcross TX m444 A4 Axis Soldering Robot

The Tsutsumi miCross TX- m444 is a soldering robot used for point and slide soldering. The X, Y, and Z axis have 400X400X100 mm range of operation, which corresponds to 200X200X100 mm range of motion. The base of the robot is made of aluminum to give it good rigidity. It has servo motor and a ball screw which help in achieving accurate repetitions and improving the carrying capacity. It has a simultaneous 4-axis PTP control. It also has simultaneous 3-axis PTP and CP functions. It has MAXEED TS-621controller which is used to check and adjust feeding amount, feed rate, and temperature of soldering wire.

It enables registering of up to 48 soldering programs. 99 soldering conditions can be added. The computer software TSCOWin manages the data required for soldering on a computer. It has a large data storage capacity, up to 6000 program steps and 3000 positions of points can be stored.

Optionally attach the “Solder Pre-heater” TW-210 and “N2 Jacket” TJ-600 accessories to ensure lead free soldering. The teaching pendant TTP-822 is also available as additional accessory.

Compact High Rigidity 4-axis Tool

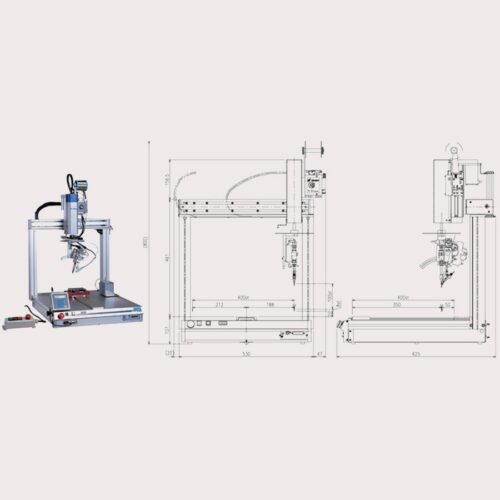

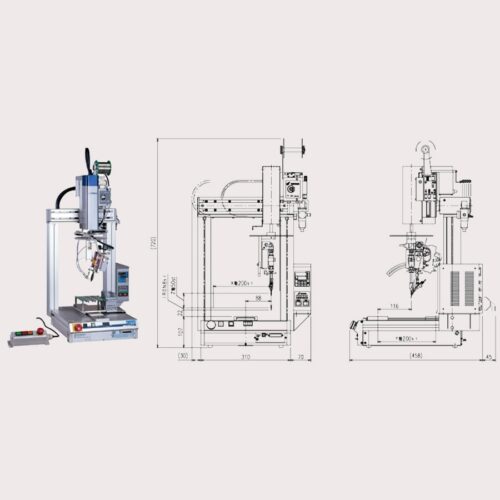

- In the robot main body, the range of operation secured 200*200*100(X,Y and Z-axis), with the compact size of only 300*370.>>Range of motion 400*400*100(X, Y, and Z axis) can correspond.

- The extrusion material of aluminum was used for a robot’s base, and high rigidity was realized.

- Using of a highly precise Ball screw and a highly precise servo control motor realized high repetition accuracy and payload capabilities.

- “Solder Pre-heat” and “N2 Jacket” which are effective option for Lead-free soldering can be attached.

- A tool part can perform PTP and CP, and correspondence also in simple slide soldering is possible for it as well as point soldering.

- A soldering controller is easy handling and carries IMPACⅡ which can perform adjustment of supply amount, supply speed of wire solder and heating time from the 1st to 3rd order.

- “TSCO”, is applied to “Windows”, can be used.

Specifications

| Model No. | mCROSS(TX-m 444) | ||||||||||||||||||||

| Power requirement | AC100V ±10% 50/60Hz 1.0KVA | ||||||||||||||||||||

| Ambient temp. Humidity, Environment | 0~40с(Non-condensing, no corrosive gas and no significant dust.) | ||||||||||||||||||||

| Air pressure | 0.4 ~ 0.5MPa ( 4 ~ 5kgf/c ㎡) Dry air | ||||||||||||||||||||

| Movement method | PTP ・ 4-axis simultaneous control ( Equipped with simultaneous 3-axis PTP and CP functions ) | ||||||||||||||||||||

| Drive system | Pulse motor, Ball screw drive | ||||||||||||||||||||

| Robot performance |

|

||||||||||||||||||||

| Program capacity | 48programs | ||||||||||||||||||||

| Data storage capacity | No. of program steps: 6000steps ・ No. of points: 3000position | ||||||||||||||||||||

| Teaching method | Direct teaching by MDI and Jogging operations with Teaching Pendant, TTP-822 (Option). | ||||||||||||||||||||

| No. of soldering condition | 99 blocks. Free program method. | ||||||||||||||||||||

| Soldering operation | Point soldering and slide soldering | ||||||||||||||||||||

| Weight | 48kg |

(*) Teaching Pendant/TTP-822 is option.

Why Choose Sumitron ?