Hakko FU-500/FU-601

Hakko FU-500/FU-601

HAKKO FU-500

- Accurate solder feeding.

- Supports solder diameter 0.3mm to 1.6mm.

- Solder feed error detection.

- Equipped with countermeasures against solder ball splash as standard.

- Easy tip replacement.

- High performance Composite tip.

- Six presets tip Temperature function.

- 300w Ultra High Power (FU-601).

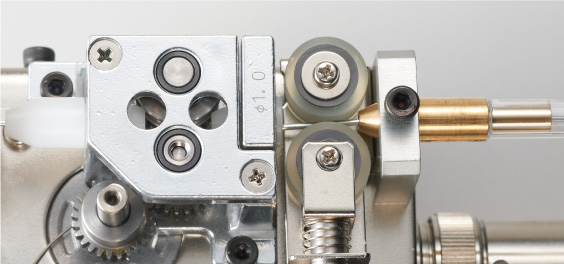

FU-500 solder feed unit

Features

- Accurate solder feeding

FU-500 features a compact drive unit that allows the solder feed unit to be brought closer to the iron. This adaptation makes it possible to increase the repeat accuracy of amount of solder feeding.

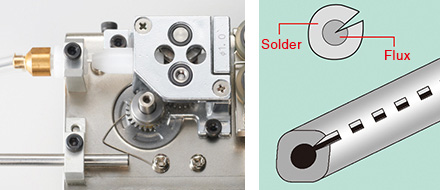

- Equipped with countermeasures against solder ball scattering as standard

As countermeasure against scatter of flux and solder balls, the unit is equipped with a mechanism that perforates into the solder wire as standard. It is also possible to change acceptable solder wire diameter by simply replacing the pulley unit.

- Supports solder diameters of 0.3 mm and up

As the unit is capable of handling extremely small solder diameter of 0.3 mm, it can be used for delicate soldering jobs. It Supported solder diameter 0.3 mm to 1.6 mm. - High-performance programming

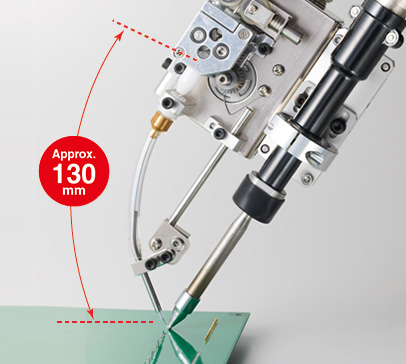

100 programs each configurable for “Point soldering” and “Drag soldering” at low price. Programs can be edited by PC via a USB connection. - Easy adjustment of solder feeding position

Adjustment of the position of solder feeding to the tip is critical for auto-soldering systems. FU-500 lets you adjust the solder feeding position just by turning an adjustment screw with a wrench.

- Solder feed error detection

With an optical sensor for solder movement, FU-500 can detect solder clogging, slipping and the end of the roll.

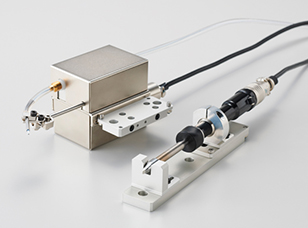

FU-601 soldering iron unit

Features

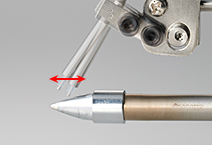

- Easy tip replacement

The position of the tip end can be easily adjusted using the tip adjustment jig unit included with FU-601. Work can be started just by removing the iron from the main unit by removing two screws, positioning the tip using the tip adjustment jig unit, and returning the iron to the main unit. Using another iron (FU-6001 or FU-6002) makes it possible to install a new tip in advance, minimizing equipment downtime.

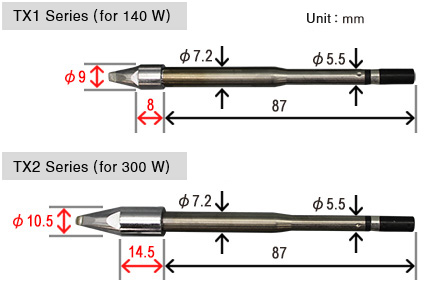

* Two types of tip adjustment jig units are available: one for TX1 series and another for TX2 series.

- High performance composite tip

FU-601 can provide excellent thermal recovery characteristic with a high performance composite tip, a tip integrated with a heating element and sensor.

- 40 types of TX2 series soldering tip are lined up

40 types of TX2 series soldering tip are lined up for a wide range of soldering conditions. The use of appropriate tip can not only improve quality and efficiency of soldering but also reduce running costs. - Six presets tip-temperature function

Tip temperature can be preset in six settings. Preset temperatures can be called from soldering conditions in the solder feed unit. - Available 2 soldering irons

Select the one to meet your requirement.

FU-6001 is straight, and FU-6002 is L-Shaped Iron.

|

|

| FU-6001 | FU-6002 |

| Model No. |

FU-500 |

|

| Power Consumption | 35 W | |

| Compatible Solder Diameters | 0.3 mm, 0.5 mm, 0.6(0.65) mm, 0.8 mm, 1. O mm, 1.2 mm, 1.6 mm | |

| Weight (not including cords) | 2.3 kg | |

| Model No. | FU-600 | FU-601 |

| Power Consumption | 140 W | 300 W |

| Temperature Range | 50-500°C | |

| Preset Temperature | 6 settings | |

| Temperature Stability | ±5 at idle temperature | |

| Dimensions (W x H x D) | 145 x 102 X 210 mm | 145 x 107 x 211 mm |

| Weight (not including cords) | 2.8 kg | 4 kg |

Why Choose Sumitron ?