In today’s fast-paced manufacturing world, automation is more than a competitive advantage, it’s a necessity. The Hakko FU-500/FU-601 system delivers industrial-grade automation to your soldering operations, enabling unmatched precision, accelerated workflows, and consistent repeatability. Designed for integration with robotic arms and automated stations, this system helps industries cut down on labor costs, boost output, and maintain impeccable soldering standards.

Whether you’re in electronics, automotive, medical devices, or telecom manufacturing, the FU-500/FU-601 system offers a smart leap toward fully automated soldering. Let’s explore why the FU-500/FU-601 combo is a smart investment for forward-thinking manufacturers.

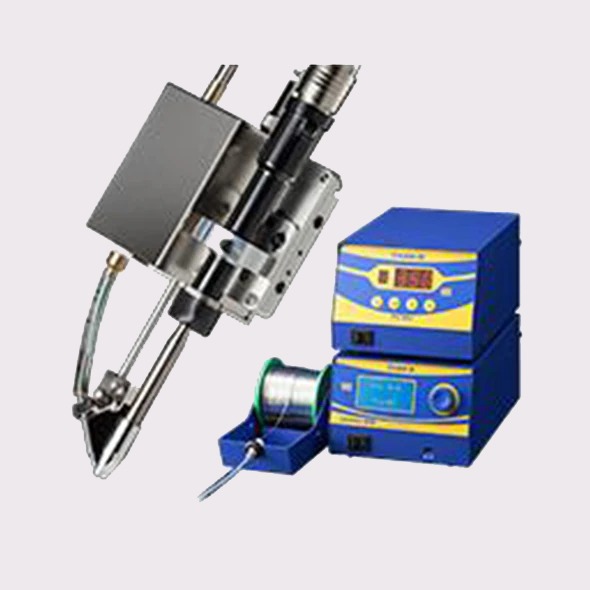

What Is the Hakko FU-500/FU-601 Auto Soldering System?

The Hakko FU-500 is a high-performance automatic solder feed unit, and the FU-601 is a 300W soldering iron unit engineered for integration with robotic soldering systems. Built for precision, this combination is especially suited for mass production lines, PCB assembly, and fine electronic components soldering.

- FU-500 (Solder Feed Controller): Delivers precise, programmable solder wire feeding for both point and drag soldering applications. It supports wire diameters ranging from 0.3 mm to 1.6 mm and includes an optical sensor that reliably detects issues like solder jamming, slipping, or end-of-roll, ensuring uninterrupted operation.

- FU-601 (Soldering Iron): A high-power, composite-tipped soldering iron that delivers excellent thermal recovery, even in high-volume production runs. Available in straight and L-shaped variants, making it ideal for robotic configurations.

Key Features That Maximize Soldering Efficiency

1. Precision Solder Feeding

The FU-500 enables precise control of solder length, speed, and volume with up to 100 programmable parameters. Whether your application demands fine-point soldering or consistent drag soldering, this unit ensures error-free, repeatable results.

2. High Thermal Performance with 300W Power

The Hakko FU-601’s ultra-high power output enables efficient handling of heavy solder joints and thermally intensive components without sacrificing speed. Its stable tip temperature control ensures precise soldering of sensitive electronic assemblies, guaranteeing reliable connections.

3. Error Detection System

A built-in optical sensor continuously monitors the solder feed. It halts the system automatically when it detects slipping, clogging, or the end of the solder roll, minimizing defective joints and rework.

4. Fast Tip Change & Adjustment

The system includes a tip adjustment jig for quick positioning and replacement, keeping maintenance downtime minimal. It’s compatible with Hakko’s TX2 series tips, supporting over 40 tip variations to suit a wide range of soldering needs.

Why It’s Ideal for Industrial & Robotic Soldering Applications

The Hakko FU-500/FU-601 system isn’t just a tool, it’s a precision automation solution trusted by industries requiring reliable soldering at scale. It seamlessly integrates with robotic arms, desktop soldering robots, or automated conveyors to deliver repeatable, high-quality joints.

Here’s how it benefits various industries:

1. Automated PCB Assembly

For high-speed PCB production, this system ensures precise solder wire feeding and consistent heat control, crucial for densely packed or multilayer boards. It effectively minimizes common defects like cold joints and bridging while reducing operator fatigue in high-volume production environments.

2. Robotic Soldering Arms

Its compact design and programmable controls make it a natural fit for pick-and-place and inline soldering robots. It enhances robotic efficiency by delivering accurate solder amounts at consistent positions every cycle.

3. Electronics & Component Manufacturing

The system delivers precision soldering capabilities for ultra-fine wire diameters and micro components, thanks to its adjustable heat profiles. This ensures minimal heat stress and optimal connection quality, perfect for delicate electronic assemblies.

4. Medical Devices & Automotive Electronics

These sectors demand high-reliability solder joints for life-saving and mission-critical components. The FU-500/FU-601 delivers repeatability and compliance with IPC standards, supporting ISO-certified production environments.

5. Aerospace & Telecom Equipment

In aerospace and telecom applications, strong, vibration-resistant solder joints that can withstand thermal cycling are essential. This system supports multi-angle tip configurations and stable soldering performance, even under extended production cycles.

6. Bottom Line: What You Gain

- Labor cost reduction through automation

- Higher throughput with lower rejection rates

- Zero-variance solder joints for quality assurance

- Seamless integration with Industry 4.0 workflows

FU-600 vs FU-601: What’s the Difference?

While the FU-601 (300W) is designed for high-thermal-load applications, the FU-600 (140W) variant can be used for lighter soldering tasks. Both support:

- Straight and L-shaped iron models

- Easy integration with soldering automation systems

- Composite tip technology for efficient heat transfer

Choosing the right model depends on your production volume, component complexity, and thermal needs.

Optimize Your Soldering Workflow with Hakko FU-500/FU-601

This high-efficiency soldering system is tailored for factories and OEMs looking to:

- Improve throughput without sacrificing quality

- Reduce human dependency and soldering inconsistency

- Gain programmable control over every soldering action

The FU-500/FU-601 combination offers a scalable, automation-ready soldering solution designed to meet the evolving needs of modern manufacturing. It empowers your production line with precision, consistency, and the flexibility to adapt to increasing complexity and volume.

Get a Quote for Hakko FU-500/FU-601 from Sumitron

Sumitron is a trusted supplier of Hakko robotic soldering equipment and industrial automation solutions. Whether you’re upgrading your production line or automating your current soldering setup, Sumitron provides expert consultation and competitive pricing for the Hakko FU-500/FU-601 system.

Get a Quote from Sumitron Today and take the next step toward smarter, faster, and more reliable soldering.

Read Also This Blog