Hakko FT-720 Tip Cleaner

Specifications

| Model No. | FT – 720 |

| Rating | 24 VDC 140mA |

| Dimensions | 67(W) × 63(H) × 94(D)mm |

| Weight | 200g |

| Power consumption | 72 W (20 V) |

| Brush rotational speed | 1670 rpm |

| AC Adaptor output voltage | 24 VDC |

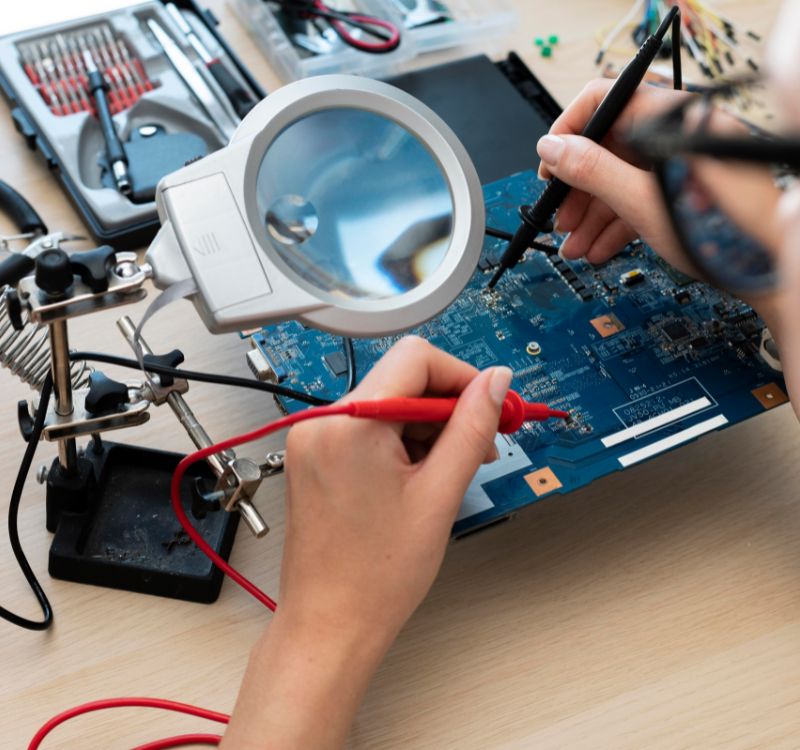

1) Quick tip cleaning

As the infrared sensor detects a tip being inserted, the brushes start rotating automatically to clean a tip quickly.

POINT

- Reduce time for tip cleaning and increase efficiency in soldering process Fea Increasing efficiency in soldering process by reducing time for tip cleaning

2) Cleaning a variety of tip shapes

FT-720 surely and quickly cleans a variety of tip shapes, and also a tip even having the guide pipe assembly on a handpiece.

3) Minimizing tip temperature drop

FT-720 can help increase productivity by shortening the cleaning time and minimizing the tip temperature drop with no use of water.

Comparison of the tip temperature drop

4) Reduction of solder balls

The narrow opening of the front cover reduces scattering of solder balls.

FT-720 helps keep the work environment nice and clean. (FOD prevention)

5) The adjustable opening size

By removing the adjuster, the opening can be wider to accept bigger size tips. Also, the removed adjuster can be stored inside the unit.

|

|

|

6) Brush lineup for different purposes

In addition to the standard brush, two more optional brushes are available (sold separately) for different purposes.

- Standard brush

- Fluoroplastic brushes

7) Long-life brush with excellent durability

Effective in reducing of solder balls while tip cleaning

Part No. A5063

8) Effective in reducing the impact of tip oxidation

Recommended for soldering with lead-free alloy or halogen-free flux

Part No. A1566

Option / Metal brush

Effective in removing solder from a tip completely

Recommended for soldering fine and precise components

Part No. A1567

9) Products for tip maintenance

- Tip cleaner FT-710

- FT-710 Tip cleaner that prevents scattering of solder balls

Insertion of a tip into FT-710 turns on the switch to start tip cleaning with brushes.

Maintenance Kit FT-700

FT-700 Tip polisher that removes oxides from a tip

FT-700 removes oxides and carbides from a tip without damaging the tip.

Hakko FT-710 Tip Cleaner

Hakko FT 710 Cleaner allows you to clean your soldering equipment efficiently. The encapsulated housing of FT 710 prevents the iron tip from splashing, which is significant cause of solder failure. In addition, it also prevents the soldering paste from entering in to the driver. For this, it uses two types of brushes for solder cleaning one is made of Resin (removes solder partially) and the other is made of metal (removes solder entirely). The tip temperature drops while cleaning eventually leading to high workability. This device is compatible with various HAKKO soldering irons and tips and is very easy to maintain

- Prevents solder from splashing

- Compatible with various HAKKO soldering irons and tips

- Controls the amount of solder to be left on tips

- Minimizes the drop of tip temperature

- Easy to maintain

- ESD safe (A ground wire is not included)

- Silent design

- Energy-saving specification with only 5W

- power consumption (AC adapter type)

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| Minimizes decrease in temperature of the tip while cleaning. | ||

| · Inserting the tip turns the brush automatically; no need to switch it on and off. · Reduces the tip cleaning time between soldering works to increase work efficiency. · The electric rotary cleaner provides a uniform final cleaning status with no differences between individuals. |

||

| Comparison of decrease in tip temperature by cleaning method | |||||||||

| If decrease in temperature is small, the time for a single cleaning also becomes short. Because cleaning is performed many times per day, the overall working time can be also shortened. | |||||||||

| Time for single cleaning (The time for a single cleaning is measured as the time until the tip temperature reaches the set temperature after cleaning.) | |||||||||

|

|||||||||

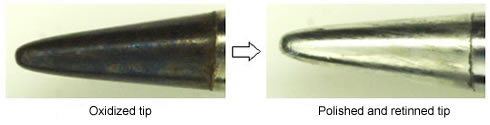

Hakko FT-700 Tip Cleaner

Hakko FT700 Tip Polisher is a device that is used for polishing the soldering tip. Polishing helps removal of oxidized material that is firmly present on the soldering tips. Polishing does not damage the soldering tip. However, it eventually increases the life of soldering tips. While polishing you must use the Chemical Paste HAKKO FS-100. The paste does not include any amount of Ammonium phosphate. If HAKKO FS 100 fails to remove the oxidized material, you can use the brush to remove the oxidized material. The use of this brush may produce small scratches on the iron plating surface of the tip.

| “Maintenance kit for oxidized soldering tips” Especially suitable for soldering tips oxidized by Lead-free solder and high temperature solder By using the brush and accessory “Chemical Paste”HAKKO FS-100: |

|

| Oxidation can be removed without causing damage to the soldering tip | |

| Diamnonium phosphate is not included | |

| Power saving with 3 power consumption. | |

|

| · Operation | ||

Oxidized tip |

|

Re-tinning is now completed. |

||||

Remove the oxidation. |

Re-tin the tip. |

Clean off FS-100 paste from tip surface. |

Feed solder onto tip. |

|||

Repeat the process twice or more. |

||||||

| NOTE: | When the tip temperature is over 400ºC, even if the oxidation film is removed by “HAKKO FT-700 tip polisher”, the tip can turn to be oxidized quickly again. |

| When the oxidation cannot be removed by the above procedure |

| When the oxidation is hard, it sometimes cannot be removed even by the HAKKO FT-700. In this case, use the brush which is included in the unit as the accessory. |

|

|

|

||

| (1) Remove oxidation the brush. | (2) Clean with FT-700 | (3) Re-tin with HAKKO FS-100 and perform the operation No.3 and 4. |

| NOTE: | When the brush is used, small scratches may be produced on the iron plating surface of the tip. Do not always use the brush, but use only when oxidation cannot be removed by cleaning with HAKKO FT-700. |

Specifications

| Model No. | FT-700 |

| Power consumption | 3W (100V), 4.5W (110 to 120V, 220 to 240V) |

| Dimensions | 70(W)×54(H)×101(D)mm |

| Weight | 0.65kg |

- Chemical Paste Fs-100

| Amount | 10g |

| Ingredients | Flux, tin(Sn) 50wt%(each) |

Industries Powered By Soldering Stations

Why Choose Sumitron ?